VMC Job Order Services

Precision & Quality Manufacturing

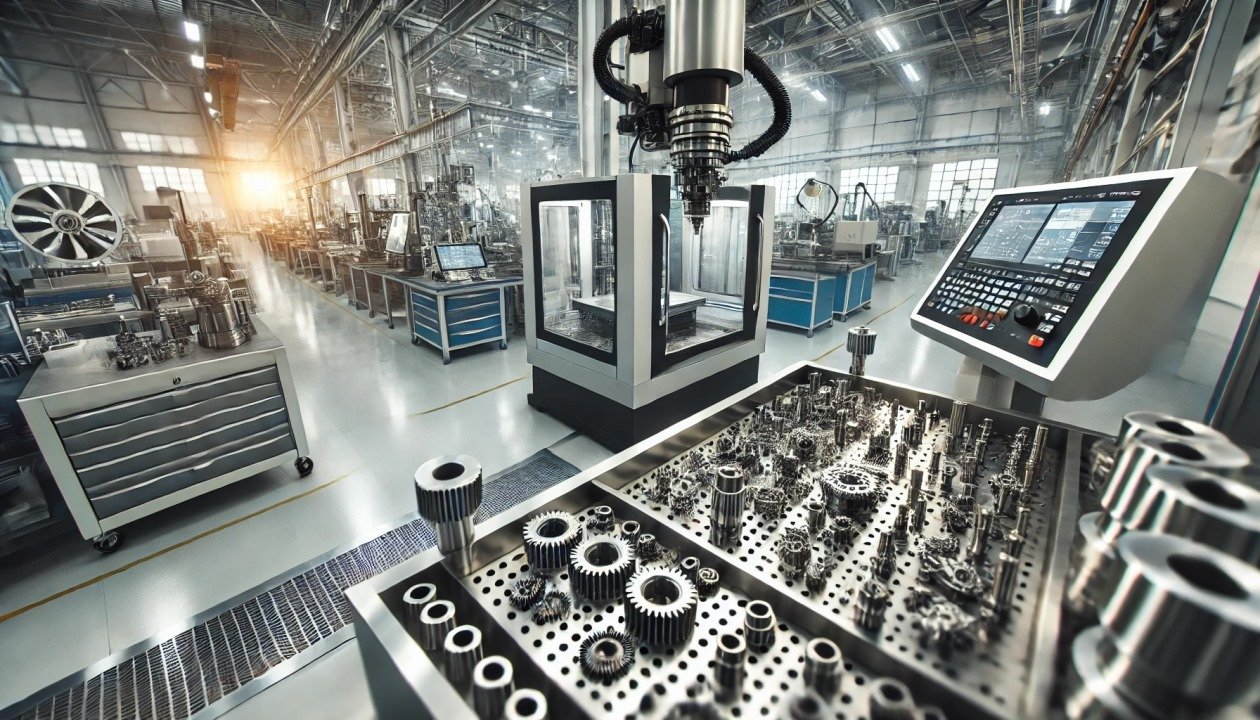

Lasak Technologies offers comprehensive VMC (Vertical Machining Center) Job Order services to cater to diverse manufacturing needs across multiple industries. With cutting-edge CNC machinery, skilled operators, and stringent quality control, we ensure precise component manufacturing with fast turnaround times.

Advanced CNC Machinery

Equipped with state-of-the-art VMC machines including FEELER MACHINE VMP32A, Vm11 model, KTM MIGHTY, and BFW for high-precision manufacturing jobs with exceptional accuracy and repeatability.

Customized Job Orders

Flexible manufacturing solutions to handle everything from single-piece prototypes to bulk production runs, tailored to meet your specific requirements and specifications.

Experienced Workforce

Our team of skilled machinists and operators brings years of VMC expertise, ensuring optimal machine utilization and superior component quality for every project.

Industries We Serve

Comprehensive VMC services for automotive, aerospace, plastics, packaging, industrial equipment, and specialized manufacturing sectors with industry-specific quality standards.

Strict Quality Control

Each component undergoes multi-stage quality inspection using advanced measuring equipment, ensuring dimensional accuracy and surface finish meet the highest standards.

Timely Delivery

Commitment to on-time delivery for every job order through efficient production planning, optimized workflows, and dedicated project management.

Our VMC Expertise

At Lasak Technologies, we specialize in machining complex components that demand precision and reliability. Our expertise spans from intricate automotive parts and aerospace components to specialized industrial fixtures and custom tooling. With our advanced VMC capabilities, we handle challenging geometries, tight tolerances, and complex multi-axis operations while maintaining consistent quality across all production volumes.

Why Choose Lasak Technologies

Modern Manufacturing Setup

Latest VMC machines with advanced control systems for superior precision and efficiency

ISO Quality Standards

Certified quality management systems ensuring consistent and reliable manufacturing processes

Competitive Pricing

Cost-effective solutions without compromising on quality or delivery timelines

Dedicated Customer Support

Personalized service with dedicated project managers for seamless communication

Rapid Prototyping

Quick turnaround for prototype development and design validation

Recent Project Categories

Plastic Injection Molds

Precision mold components with complex cooling channels and intricate surface finishes

Automotive Components

Critical engine parts, transmission components, and chassis elements requiring tight tolerances

Jigs & Fixtures

Custom manufacturing aids and assembly fixtures for improved production efficiency

VMC Machine Capability and Selection

We start every VMC job order by evaluating part complexity, material, and production needs to select the optimal machine. Our advanced VMC and HMC machines handle diverse materials and geometries with precision. This careful process ensures high accuracy, efficiency, and timely delivery for every project.

Our VMC & HMC Machines include:

- FEELER MACHINE VMP32A: Ideal for high-precision machining with robust capabilities.

- Vm11 model: A versatile machine known for its reliability and efficiency in various applications.

Precision Programming and Tooling Setup

Post VMC selection, our engineers develop detailed G-code programs using advanced CAM software, defining precise tool paths and cutting parameters. Each program is rigorously simulated to ensure "first-time right" production and minimize errors. Simultaneously, technicians meticulously prepare all necessary tooling, including cutting tools, holders, and workholding fixtures, inspecting them for accuracy. Proper workholding setup is crucial for part stability and maintaining dimensional integrity during machining. This dual focus on intelligent programming and precise tooling ensures successful VMC job order execution with high precision and superior finish.

Quality Assurance and Production MonitoringLorem ipsum

Throughout VMC job execution, stringent quality assurance is paramount. Operators continuously monitor key dimensions and surface finishes using precision instruments like calipers, micrometers, and CMMs, enabling immediate adjustments. Post-machining, every part undergoes a comprehensive final inspection to meet all customer specifications. Detailed reports document compliance, while continuous monitoring of machine performance and tool life drives process improvements. This systematic approach ensures all VMC job orders consistently meet or exceed client expectations for high-quality components.

A SUMMARY OF THIS PROJECT

This project highlights the expert Vertical Machining Center (VMC) services offered for various industries, specializing in tool and die manufacturing. The company uses advanced multi-axis VMC machines to handle high-precision job orders involving metals, plastics, and composites. Key offerings include: High-Precision Machining for both single and bulk orders. Tool & Die Projects with detailed tooling, molds, and custom tool creation. Advanced Machining Capabilities ensuring superior finishes and complex geometries. Cost-Effective and Timely Delivery, maintaining quality while meeting deadlines and budget requirements.