Our Journey in E-Commerce Development

Tesla Valve Fluid Optimization |Reverse Engineering Expert

Automated Poultry Vaccinator Design -Retrofitting Project

The poultry industry is a vital contributor to global food security and rural livelihoods, particularly in developing countries. Vaccination plays a crucial role in maintaining poultry health, preventing disease outbreaks, and ensuring high productivity. However, traditional manual vaccination methods are often labor-intensive, time-consuming, and prone to human error. This not only compromises vaccine effectiveness but also increases the risk of disease spread. In response to these challenges, automation in poultry vaccination has emerged as a promising solution. The Automated Poultry Vaccinator Design – Retrofitting Project aims to enhance existing manual or semi-automated systems by integrating advanced automation technologies, improving efficiency, precision, and animal welfare.

Problem Statement and Need for Automation

Traditional poultry vaccination processes are highly dependent on manual labor, which introduces several challenges in terms of accuracy, consistency, and hygiene. Manual vaccinations are usually done by skilled workers who administer doses to each bird by hand, a method that is both time-consuming and prone to errors such as underdosing, overdosing, or missing birds entirely. Additionally, this approach often causes stress to the birds and poses biosecurity risks due to repeated human-animal contact. In large-scale poultry operations, these inefficiencies result in significant economic losses and reduced productivity.

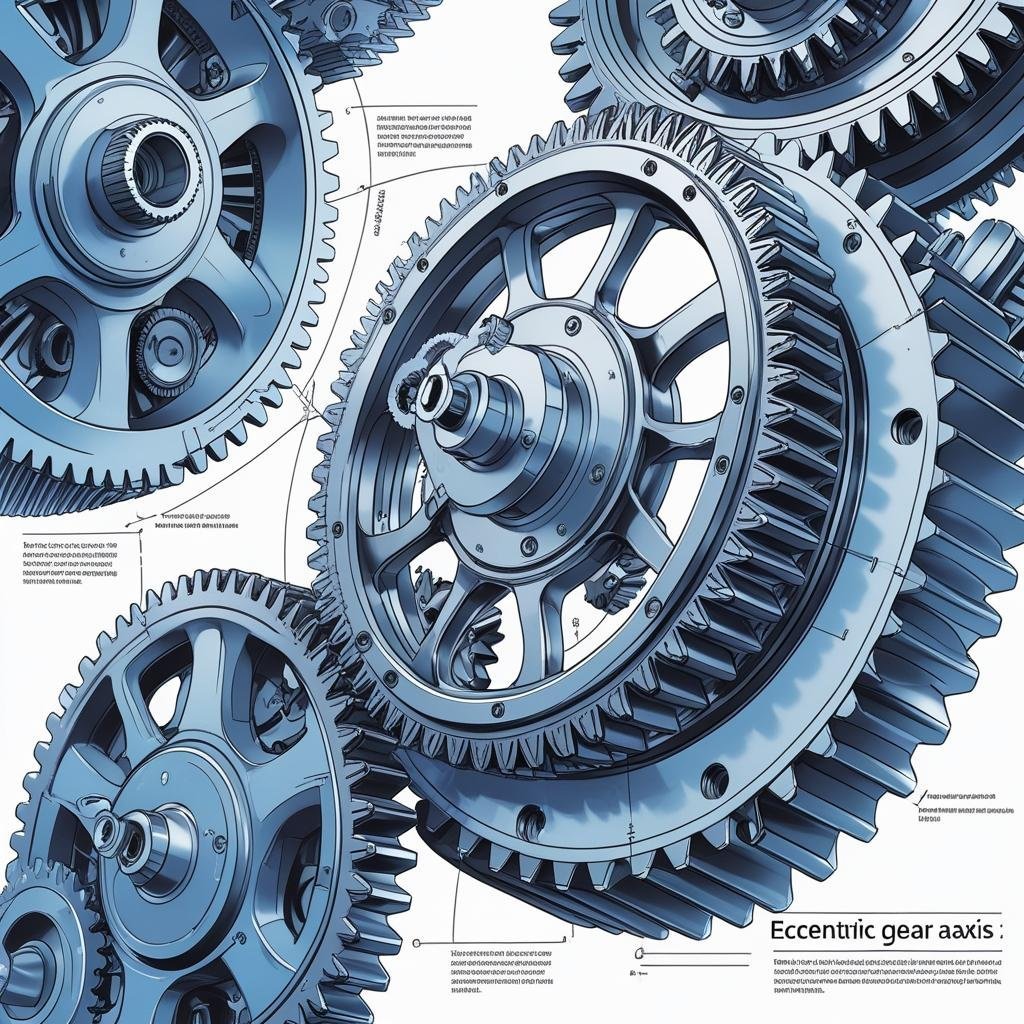

Retrofitting Strategy and System Components

The retrofitting strategy involves enhancing existing poultry vaccination setups using automation technologies without the need to replace the entire system. The project proposes the integration of key components such as programmable microcontrollers (e.g., Arduino or Raspberry Pi), motion-sensing devices, precision syringe mechanisms, and pneumatic actuators. These upgrades are tailored to suit existing vaccination tools and cages, ensuring minimal structural changes and cost implications. The goal is to automate critical steps in the vaccination process: identifying the bird, positioning the applicator, delivering the vaccine, and resetting the system for the next bird.

Automated Poultry Vaccinator Design -Retrofitting Project

Retrofitting is a cost-effective approach, allowing existing infrastructure and equipment to be upgraded rather than replaced entirely. This project focuses on modifying current vaccination setups with automated components such as precision nozzles, pneumatic arms, microcontrollers, and sensors. The goal is to develop a system that can accurately vaccinate a high volume of birds in a short time with minimal human intervention. This introduction sets the stage for a broader understanding of the project's relevance in modern poultry farming and its potential to revolutionize vaccination practices, ultimately contributing to safer food production and improved farm profitability.